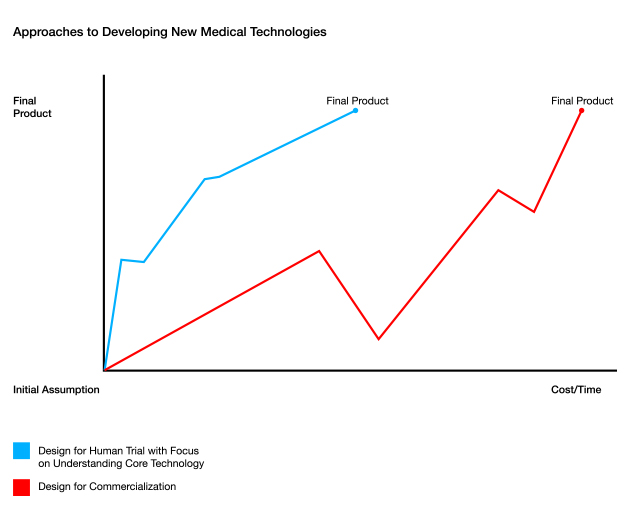

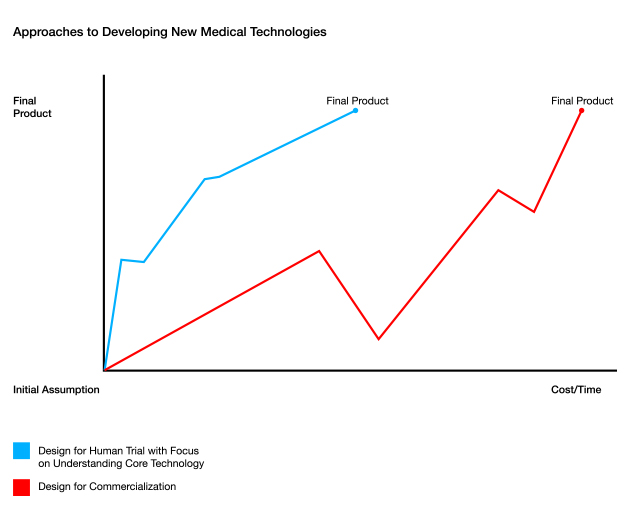

Successfully bringing a new medical technology to market is no small thing. It’s a journey fraught with a mix of high risk and great opportunity. There are three key paths to bringing new medical devices to market: develop for commercialization from the start, focus first on designing for trial, or develop for trial while suspending design efforts until the core technology is fully understood. Arguably, when developing a novel technology, the latter approach can have considerable advantages.

Design for Commercialization: The excitement of commercializing a product, compounded by the desire to make a real difference in lives, can cloud judgment and lead to teams trying to design the final product far too early in the development cycle. While this approach can work well for a device based on existing technology, truly novel technology often has too many unknowns, making it risky and difficult to start designing the final product too soon.

Design for Human Trials. With new technologies, it’s important to identify the high-risk pieces of the system as early as possible. Unfortunately, these pieces may not reveal themselves until the first human trial. Lab-based simulations and animal trials can give you vital data for making these predictions, but these models are never a perfect representative of a human. It’s only when the first human trial is run that we can really begin to understand how changes in these high-risk elements may ripple and cause modifications to the final design.

Once these variables are known, it’s possible to design flexibility into the system in order to accommodate for possible changes. The downside of this approach is that this flexibility and risk mitigation comes at the expense of more complicated products from both the engineering and user perspectives. For example, knobs may need to be designed into the system that often will not be necessary in the final design when the novel technology is better understood. While designing for human trials in this way can mitigate risk, the trade-off in adding complication is far from ideal.

Design for Human Trial with Focus on Understanding the Core Technology. A variation to the design-for-human-trials approach is to minimize the effort put into early-stage product design and focus as first on understanding the novel technology. Often, there are many pieces of a medical product that are not specialized technology (batteries, displays, etc.). Even so, designing these elements into a product can add substantial effort and cost, no matter how “off the shelf” they are. Also, correctly choosing the appropriate pieces (battery size, display size, etc.) can be difficult when the underlying novel technology and its interaction in a clinical setting are not fully understood.

To allow ourselves to focus on developing the core technology, rather than fully designing a product, we can leverage existing technologies, cobbling together a working system by pairing the new technology with existing components in Frankenstein fashion.

Let’s consider an example of a hypothetical novel technology that uses ultrasound to non-invasively measure blood sugar levels for people with diabetes. The initial belief is that the product needs to be a portable device that takes blood-sugar-level measurements and shows them on a built-in display. A team designing for commercialization might well make a decision to have the display show immediate blood sugar level and a warning when it’s too high. Developing this product would require substantial effort to be put into measurement accuracy and reading calibration.

Through the course of development, however, the team finds out that the absolute measurement ability of the new technology is not that all that accurate or clinically usable, even with calibration. However, the relative measurement over the course of the day is excellent. This discovery reveals that the real value of the system is plotting the blood sugar level over the course of the day and having associated food intake correlated with this data. Since making continuous measurements that can be downloaded is now the goal, the device’s form factor needs changed to be body worn. It will also need a simple way to input food consumed in order to correlate intake with blood-sugar-level measurements. These changes mean that battery recharge requirements have increased significantly, due to the combination of the smaller form factor and the continuous monitoring.

Alternatively, a team designing for human trials while focusing on the core technology would keep the device use-case agnostic until its capabilities are more fully understood. The minimal device could be a primary cell (non-rechargeable) operated prototype that has no display or recharge capability. Use of a Bluetooth Low Energy (BLE) module would allow data to be downloaded at any time, with download intervals from instantaneous, to weekly, or as long as the storage capabilities allow. A BLE-enabled device such as an Android smartphone could easily be configured to run an app capable of downloading and displaying the data. As the trial progresses and the primary technology is better understood, there is ample flexibility to change the user-interface and design the rest of the details of the system. With this approach, development dollars are far less often wasted by designing for unproven assumptions. In this example, the team designing for commercialization would have spent considerable amounts of time and money developing the display, only to realize that the smaller, body worn version of the device needs no display.

The bottom line

Creating a simple-to-use product is vital to creating a great user experience in any industry, but in the medical industry, simplification can, quite simply, save lives. Simplification can only occur properly when you know exactly what needs to be designed, which almost never is the case prior to a clinical trial. Suspending design of the final product until the new technology is understood and use cases have been revealed through human trials enables us to work more efficiently and minimize the risks of spending time and money developing the wrong product or an overly complicated product.

Let’s consider an example of a hypothetical novel technology that uses ultrasound to non-invasively measure blood sugar levels for people with diabetes. The initial belief is that the product needs to be a portable device that takes blood-sugar-level measurements and shows them on a built-in display. A team designing for commercialization might well make a decision to have the display show immediate blood sugar level and a warning when it’s too high. Developing this product would require substantial effort to be put into measurement accuracy and reading calibration.

Let’s consider an example of a hypothetical novel technology that uses ultrasound to non-invasively measure blood sugar levels for people with diabetes. The initial belief is that the product needs to be a portable device that takes blood-sugar-level measurements and shows them on a built-in display. A team designing for commercialization might well make a decision to have the display show immediate blood sugar level and a warning when it’s too high. Developing this product would require substantial effort to be put into measurement accuracy and reading calibration.