Original Equipment Manufacturers (OEMs) are increasingly seeking sophisticated thermal solutions to improve medical device performance. Layered heater technology is characterized by its thin profiles, precise temperature control, and swift response times, making it suitable for a diverse range of applications ranging from analytical instruments, like gas chromatography and mass spectrometry, to critical medical equipment, including kidney dialysis machines and respiratory therapy devices. Here, we explore how the transition from traditional heaters to advanced, layered heater technologies impacts device design.

The move to advanced heater solutions is motivated by the demand for medical devices that are not only compact and energy-efficient but also reliable and consistent in operation. The layered heaters’ thinness and the ability to integrate temperature sensing close to the heating surface provide unparalleled accuracy and control. As the industry trends towards the development of home-care medical devices and the pursuit of miniaturization, the importance of ensuring compliance with rigorous medical standards and safety regulations becomes increasingly pertinent.

The Critical Role of Thermal Management in Medical Devices

Thermal management within medical devices, clinical diagnostics instruments, and analytical instruments involves the sophisticated control of temperatures to prevent overheating and ensure devices operate within their optimal performance range. Proper thermal regulation is vital because even slight deviations can lead to device failure, diminished treatment effectiveness, or serious patient safety risks.

Effective thermal management is crucial for devices that generate significant heat during operation or that use heat as part of therapeutic treatments. Examples include maintaining body-temperature fluids in dialysis machines or regulating the temperature of surgical tools to avoid tissue damage. This precise temperature control is essential for the success of treatments and the safety of patients.

Emerging Heater Technologies Transforming Medical Applications

As Chief Systems Designer, I’ve overseen the integration of various advanced heater technologies designed to meet the stringent performance and safety standards required in the medical field. These include:

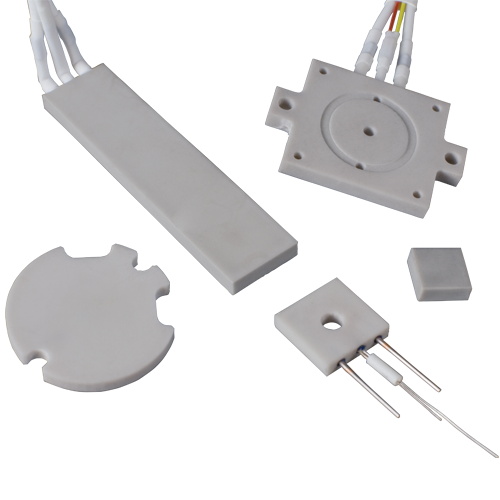

- Layered Heater Technologies: These advanced systems feature thin, efficient layers that provide precise temperature control and rapid response times. They are ideal for applications requiring strict temperature regulation, such as in analytical instruments like mass spectrometry or critical care devices such as respiratory therapy equipment.

- Integrated Temperature Sensing: Modern medical devices increasingly integrate temperature sensing directly within the heating element. This integration enhances the accuracy and responsiveness of temperature control, which is crucial for applications where specific temperature maintenance is vital for effective treatment and safety.

- High-Efficiency, Ultra-Thin Heaters: The push towards device miniaturization in the medical field requires components that are compact yet powerful. Ultra-thin heaters are designed to fit into small spaces without sacrificing performance, making them ideal for portable medical devices used in home care settings. This aligns with the industry’s shift toward developing patient-friendly, home-based treatment options.

Additionally, these heater technologies boast capabilities such as withstanding high temperatures and maintaining thermal stability over extended periods. Their design allows for customizable shapes, sizes, wattage, and heating patterns, which facilitates seamless integration into various medical applications. The energy efficiency of these heaters also plays a critical role in minimizing heat loss and maximizing performance, crucial for medical settings where operational efficiency can significantly impact overall outcomes.

Addressing the Challenges in Advanced Thermal Solutions

The introduction of sophisticated heating technologies into medical devices brings a set of complex challenges that must be carefully managed. Ensuring safety and compliance is paramount, as medical devices are some of the most heavily regulated products globally. Advanced heating solutions must not only provide effective temperature control but also ensure safety, requiring rigorous testing and adherence to international safety standards such as IEC 60601-1-11. This standard outlines specific safety requirements for medical electrical equipment and is critical for gaining approval to market and sell new medical devices.

Achieving high thermal efficiency is essential to prevent overheating, enhance energy efficiency, and minimize operational costs. This involves optimizing heat transfer capabilities, improving insulation, and selecting materials that exhibit excellent thermal properties. Each of these factors plays a critical role in the development of safe and effective medical devices.

Furthermore, the development of cutting-edge thermal solutions can be both complex and costly. Manufacturers must balance these factors with the need to produce affordable medical devices. This balance is crucial to ensure that advanced medical technologies remain accessible to healthcare providers and patients alike. Balancing cost and complexity requires innovative design strategies, efficient manufacturing processes, and careful material selection to ensure the final product is both effective and economically viable for the market.

The advantages of layered heater technology

Traditional heating solutions have long relied on nichrome element wires embedded within magnesium oxide insulation. These products, such as cartridge and tubular heaters, have been foundational yet come with inherent limitations: They often struggle with heat distribution and temperature stability, leading to energy inefficiency and environmental risks due to high operating temperatures and potential insulation breakdown. They also must operate at lower watt densities leading to larger physical sizes for the same power level.

Layered heater technology marks a significant leap forward, employing meticulously deposited thin layers of heating elements. These layers, often as thin as a fraction of a human hair, are engineered to achieve optimal thermal performance. By stacking layers with precise control, these heaters provide unmatched temperature uniformity and quicker thermal response times, allowing for precise thermal expansion matching, which is crucial for maintaining structural integrity and functional reliability under varying thermal conditions.

The materials used in layered heaters, such as aluminum nitride or other advanced ceramics, play a crucial role in their performance. These materials are selected for their high electrical insulation and superior thermal conductivity, crucial for safe and efficient operation. In the design of MedTech equipment, this ensures high precision and adherence to stringent safety standards, critical for patient care devices. The ability to pattern heater circuits further allows for tailored solutions to specific heating needs, accommodating various applications with enhanced design flexibility.

Ultimately, layered heater technology not only represents a significant technological advancement but also a paradigm shift in thermal management and is set to redefine standards and expectations within the MedTech industry. The ongoing push for greater efficiency, miniaturization, and safety points to broader adoption of these heaters.

Future Directions in Thermal Management

Looking forward, the field of thermal management in medical devices is set for further innovation, with significant advancements anticipated in miniaturization, improved energy efficiency, and the integration of intelligent technologies. Future developments are likely to feature smart thermal management systems equipped with sensors and IoT connectivity, enabling real-time monitoring and precise adjustments to optimize treatment outcomes.

Additionally, the potential integration of AI and machine learning into thermal management systems holds the promise of revolutionizing personalized patient care. By optimizing heater performance based on real-time data and individual patient needs, these technologies can enhance the efficacy of treatments and significantly improve patient outcomes.

Conclusion

As medical technology continues to advance, the role of sophisticated thermal management systems will remain crucial. Ongoing innovations in heater technologies promise to enhance device performance, improve patient safety, meet the complex demands of next-generation medical devices, and facilitate the development of new and effective medical treatments. As we look to the future, the integration of advanced thermal solutions will continue to be a critical area of focus, promising significant impacts on the future of healthcare technology.