Medical Device Software Safety, Quality, and Compliance: What Really Makes A Difference?

A look into the importance of high-quality software in the medical device industry.

A look into the importance of high-quality software in the medical device industry.

When assessing the root cause of a use error, look at the user interface before pointing fingers.

The technology platform has already gone global and has the potential to be a true breakthrough in screening and detecting several types of cancer.

Device manufacturers are concerned about data availability and security, as well as risk to their brand.

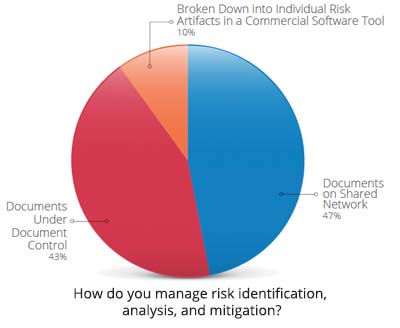

With the increased complexity of devices, a streamlined approach to managing product development risks and documenting compliance is challenging but perhaps more important than ever.

Manufacturers that make custom devices must move beyond conventional engineering practices to an automated and collaborative engineer-to-order process.

As medical device complexity grows, the product development process often needs to improve in order to maintain device quality and safety, foster innovation, and reduce costs. Yet teams looking to make improvements often encounter resistance from management. This Ask the Expert focuses on how you can overcome barriers to improving the medical device development process.

As medical device complexity grows, the product development process often needs to improve in order to maintain device quality and safety, foster innovation, and reduce costs. Yet teams looking to make improvements often encounter resistance from management. This Ask the Expert focuses on how you can overcome barriers to improving the medical device development process.

CAPA provides visibility into critical product quality characteristics, failures/ non-conformances, and resolutions to these issues for smarter decisions across the global, extended enterprise. With the right solution, design, manufacturing and quality improvement teams can share the same views of the information they need to directly impact Six Sigma and Lean initiatives.

CAPA provides visibility into critical product quality characteristics, failures/ non-conformances, and resolutions to these issues for smarter decisions across the global, extended enterprise. With the right solution, design, manufacturing and quality improvement teams can share the same views of the information they need to directly impact Six Sigma and Lean initiatives.

Despite a clear need to get better development lifecycle management solutions in place, companies are restricted by tight budgets, validation overhead, and bureaucracy. In this Q&A, Matt Harp and Angie Pepiot at Seapine Software share their insights.

Despite a clear need to get better development lifecycle management solutions in place, companies are restricted by tight budgets, validation overhead, and bureaucracy. In this Q&A, Matt Harp and Angie Pepiot at Seapine Software share their insights.

Being in compliance means operating your business in a manner that means less risk, better quality, safety and governance. Compliance management software is designed to help foster this concept, so what do you need it to be?

Being in compliance means operating your business in a manner that means less risk, better quality, safety and governance. Compliance management software is designed to help foster this concept, so what do you need it to be?