Does Your Device Play Well with Others?

The comprehensive approach to human factors considers how a product operates alone, interoperability in larger settings, and data management.

The comprehensive approach to human factors considers how a product operates alone, interoperability in larger settings, and data management.

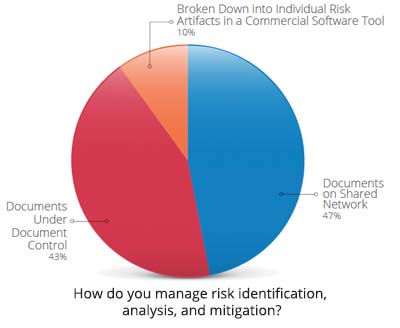

With the increased complexity of devices, a streamlined approach to managing product development risks and documenting compliance is challenging but perhaps more important than ever.

Using a checklist to find the best outsourced partner to develop your medical device can help reduce errors, increase safety and ultimately improve performance outcomes.

Using a checklist to find the best outsourced partner to develop your medical device can help reduce errors, increase safety and ultimately improve performance outcomes.

Multi-material molding, a process whereby at least one melt processible material is bonded with at least one other material to produce a single, molded component, allows designers to optimize material properties and costs, eliminate assembly processes, and even invent ground-breaking products that could not be manufactured otherwise.

Multi-material molding, a process whereby at least one melt processible material is bonded with at least one other material to produce a single, molded component, allows designers to optimize material properties and costs, eliminate assembly processes, and even invent ground-breaking products that could not be manufactured otherwise.

Telling the parent their child has a temperature of 38.674 °C may be an impressive engineering feat, but the last two digits have no real value and any time spent in development getting there was misspent.

Telling the parent their child has a temperature of 38.674 °C may be an impressive engineering feat, but the last two digits have no real value and any time spent in development getting there was misspent.

Whether you’re an engineer, designer, or technical tinkerer, here’s a basic road map to a few of the most important aspects of modern 3D printing.

Whether you’re an engineer, designer, or technical tinkerer, here’s a basic road map to a few of the most important aspects of modern 3D printing.

Despite a clear need to get better development lifecycle management solutions in place, companies are restricted by tight budgets, validation overhead, and bureaucracy. In this Q&A, Matt Harp and Angie Pepiot at Seapine Software share their insights.

Despite a clear need to get better development lifecycle management solutions in place, companies are restricted by tight budgets, validation overhead, and bureaucracy. In this Q&A, Matt Harp and Angie Pepiot at Seapine Software share their insights.

Prototyping is expensive. But creative construction and use of prototypes can dramatically improve the development process and save the development team a significant amount of time and money.

“If you are doing a wound care dressing, what is unique about the product, what are you doing differently than what is already in the market, what is it intended to be used for, who is using it, and where is it being used… All of these pieces of information help you decide how to proceed.” – Jeff Kaminski , President of MBK Tape Solutions. Excerpts from an interview.

“If you are doing a wound care dressing, what is unique about the product, what are you doing differently than what is already in the market, what is it intended to be used for, who is using it, and where is it being used… All of these pieces of information help you decide how to proceed.” – Jeff Kaminski , President of MBK Tape Solutions. Excerpts from an interview.

When developing highly complex medical devices, the mountain of “interesting” ideas that result from traditional brainstorming all too often buckles under technical scrutiny. A more efficient and effective way to generate and refine ideas that are technically viable is needed.