Researchers at Carnegie Mellon may have found a way to help industry experiment with 3-D printing at a larger scale and at a higher quality. By converting a standard desktop 3-D printer into a bioprinter, it may be possible to print a larger volume of artificial human tissue—even possibility at the scale of a human heart.

“Usually there’s a trade-off because when the systems dispense smaller amounts of material, we have more control and can print small items with high resolution—but as systems get bigger, various challenges arise,” said Adam Feinberg, associate professor of materials science and biomedical engineering at Carnegie Mellon in a press release.

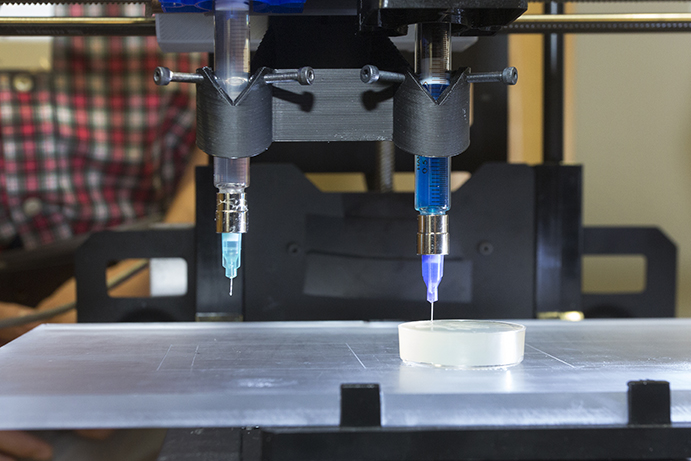

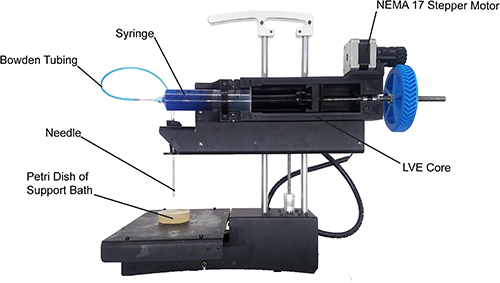

Researchers created a large-volume syringe pump extruder that is compatible with open source fused deposition modeling printers, providing a cheaper solution for folks who work with 3-D printers. Since the design is open source, it allows anyone to build the system. “We envision this as being the first of many technologies that we push into the open source environment to drive the field forward,” says Feinberg. “It’s something we really believe in.”

The researchers published instructions on how to install the extruder into a general commercial plastic printer in a paper published in HardwareX.

Feinberg says the bioprinter can be built for less than $500—a significant drop from the typical $10,000–20,000 cost of 3-D bioprinters. His lab is working to create open source biomedical research with the goal of helping other researchers continue to innovate and develop technologies faster. “It’s really about democratizing technology and trying to get it into more people’s hands,” he said.