In today’s healthcare world, every day there’s news about a new medical device that’s been made using 3-D printing technology. Broadly speaking, manufacturing devices using 3-D printing, or additive manufacturing (AM) is a process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing.

A study published by Deloitte University Press estimates the overall market size for the AM industry at $2.2 billion in 2012, with a compound annual growth rate of 14.2 percent. Medical applications accounted for 16.4 percent of the total system-related revenue for the AM market in that year. A key reason for this is that AM capabilities align well with the needs of medtech’s medical device segment, which serves a broad, geographically distributed population of service providers that in turn, serves an even larger end market of health care consumers.

Many medical devices, such as hearing aids, dental crowns, and surgical implants, are relatively small in size and therefore, are suitable for the production envelope sizes available through common AM systems. Furthermore, these products are value-dense—that is, they combine relatively high value with relatively small physical volume—and the high level of customization available with AM makes this technology well suited for custom-fitting products to individual patients, an important factor in clinical efficacy.

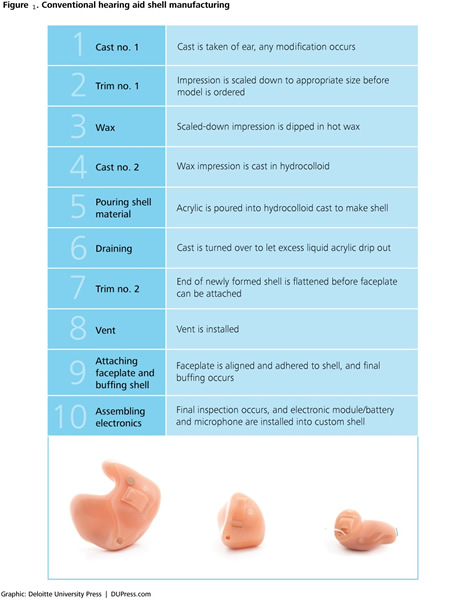

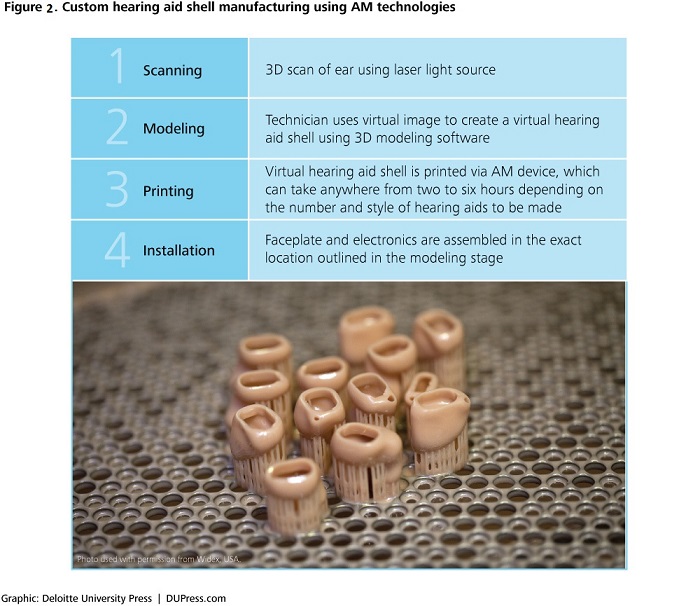

Around 95 percent of hearing aids are 3D printed today (see figures 1 and 2). In the dental area, 18 million unique retainer molds that are currently 3D printed. Additive manufacturing also has a lot of relevance in pediatric devices, so that as the patient grows, a newer, bigger version of the device, can be customized for that child.

Author of the Deloitte study Glenn Snyder, a Principal in Deloitte’s Life Sciences/Strategy practice and leader of Deloitte’s Medical Technology segment, chaired a session at this year’s AdvaMed on how the healthcare industry is currently using 3-D printing and to discuss what the future holds for this revolutionary technology.

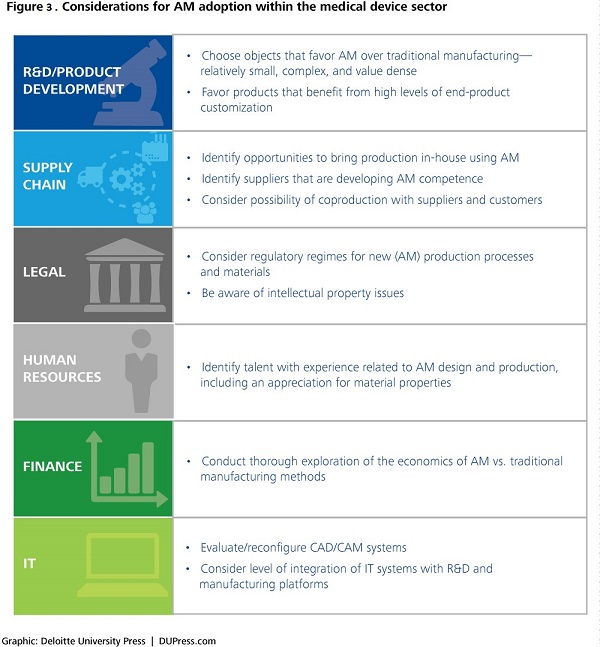

Additive manufacturing is becoming an increasingly hot topic, says Snyder, and has the potential to change not only the supply chain for med-tech, but also the way products are designed. Today most companies are using 3-D printing capabilities for prototyping their product, with the technology allowing companies to do rapid prototyping and a way to involve customers in the process.

But Snyder sees an evolution of this technology along two axes of innovation: supply chain evolution and product creation. Companies will begin using 3D printing for making a product that is currently difficult to make using subtractive manufacturing techniques. For instance, Snyder provides the example of a hip implant, which features a highly articulated surface that can help with bone growth. “An implant with this level of complexity will be very difficult to manufacture using subtractive manufacturing techniques,” Snyder explains. Another product segment this is being seen is for making exoskeleton types of products such as prosthetics. In such cases, additive manufacturing has the ability to customize the product so that it can perfectly match the limb of the person.

Snyder also points to another area which is witnessing growth due to AM technology: “In remote locations where there are inherent supply chain difficulties, and challenges in getting finished products easily out to point of care, such as in branches of military or in emerging markets, 3-D manufacturing can have a lot of value.”

Where does AM hold most potential? Snyder points out that additive manufacturing is currently most relevant to manufacturing value-dense products such as implants. Such products have lot of value, have to be manufactured with precision, high quality and durability. And additive manufacturing has a natural fit with those products. It’s also applicable for products in which, because of AM techniques, you can unlock some of the traditional manufacturing barriers and boundaries, which subtractive techniques would not allow you to do. Using AM, you can come up with new designs, a lighter structure, sophisticated internal structural support, surface modifications or patterns that allow for bone growth or better adherence etc. Also the ability to match a patient’s anatomy can be very relevant for some AM products.

What excites Snyder most about the 3-D printing technology is to do the combination of both the actual product evolution, where products are customized for patients, and more creative designs are produced, and the supply chain aspect of this, whereby you have the ability to make a product, on location. “You can make a product that is customized for the patient, on demand, that doesn’t require a suitcase full of diff sizes of devices in the OR to fit the patient best – product that’s perfectly designed just for the patient. And because you can get a product that’s made for that specific patient, it’s better for them, and improves the efficiency of the clinical setting,” Synder sums up.