Final Rule: CGMP Requirements for Combination Products and Guidance Document; the Combination Products CGMP Draft Guidance

Do take the time to understand the Comments in the Rule, they provide key Agency insights. A few points to consider from the Combination Products CGMP regulation and the Draft Guidance when preparing your approach to comply with the Stability Testing requirements.

- Comment 23 of the combination products CGMP addresses the role of reserve samples as important in addressing certain product complaints, evaluating stability concerns and assessing the causes of adverse events. This comment provides important guidance on reserve samples which will affect your stability program.

- Comment 25 further emphasizes the requirements of a written stability program that addresses the storage and expiration dating. Also identifies 201.17, which discusses location of the Expiration Date.

- To be able to answer these requirements, as noted above, a thorough review of the ICH guidances will be important. Note, when the device is also the container closure system, you may need to look at the container closure requirements and ensure your stability program also addresses them.

- The CP CGMP draft guidance provides several insights on how to comply with the stability, expiration dating and the reserve sample requirements. It indicates that when the drug makes contact with the device, both must be a part of the stability program. If a device constituent part is incorporated into a drug container it may raise additional considerations, and you may need to look at your design control system.

- The CGMP Requirements for CP – draft guidance points out that the purchasing agreement system of your purchasing controls should indicate the manufacturer of the combination product is to be notified of any changes. This is to be able to assess the impact to stability testing and other key CGMP systems.

- An important insight that should be well understood is “for a single-entity combination product, testing must be performed on the drug constituent part in the finished combination product”. This may impact your drug analytical method, its validation, and how you set the specification for drug identity, strength, quality and purity. This specification may impact the expiry date and the storage conditions as specified on the label.

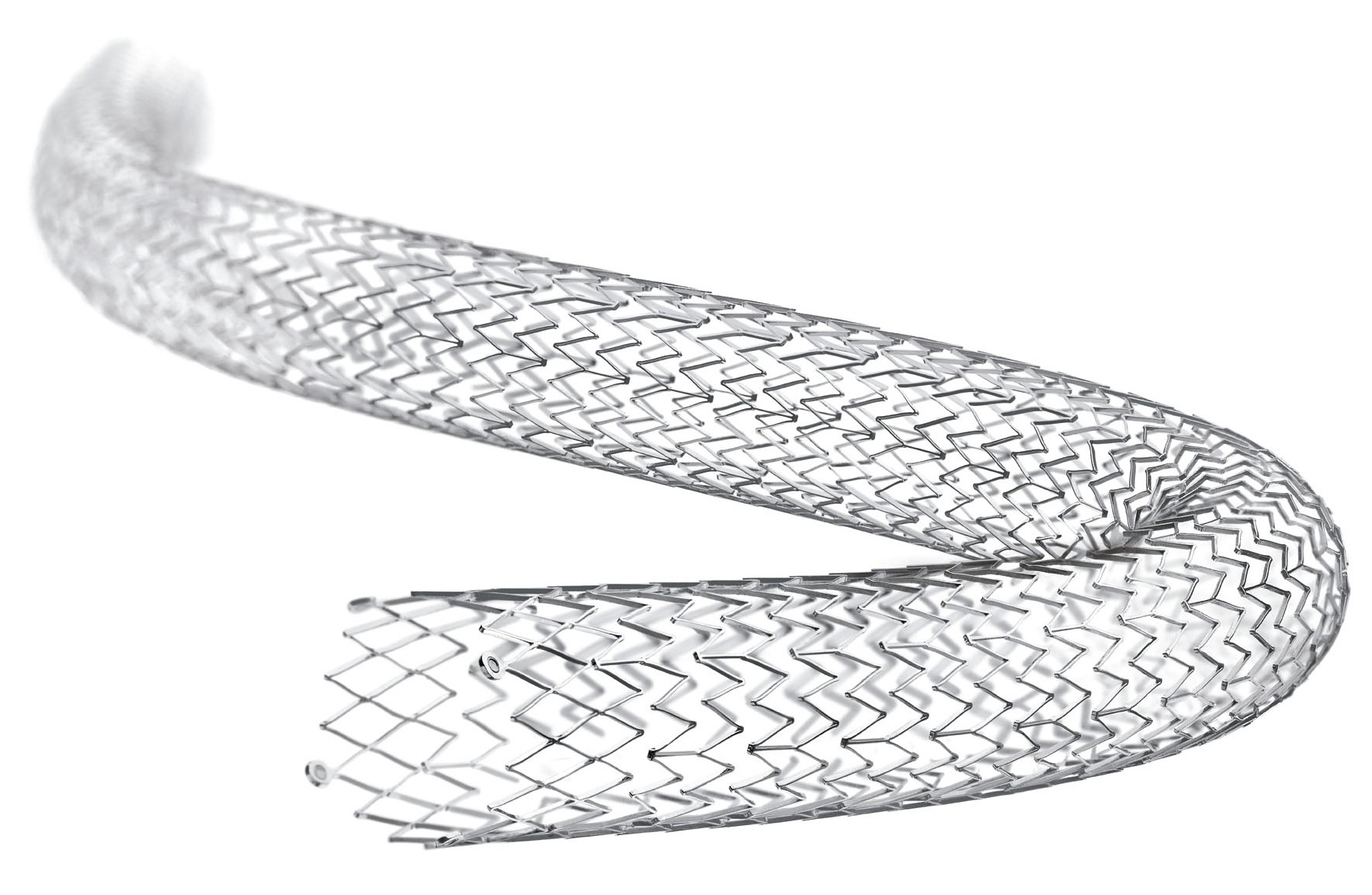

- One of the examples the CGMP Requirements for CP – draft guidance discusses is drug-eluting stents. It indicates stability testing should include such characteristics as: Appearance, assay/drug content, impurities/degradation products, rate of drug release, particulate matter, sterility and package integrity. This is a good guide to help you establish the requirements for quality, strength and purity specifications to be tested during stability.

During this article it has been our objective to share with you insights on the many quality systems Sterility Testing can impact. This is not an exhaustive list; it is intended to stimulate your strategy. Integration of drug CGMP’s into a device environment is a significant undertaking that should be led by senior management with a commitment to a long-term vision of where they expect their combination product business to be. We have discussed some very complicated requirements that will require time, resources and a sustained effort to bring about the commensurate skills necessary to meet the needs of your combination products business objectives.

Resources

- FDA. INSPECTIONAL TECHNICAL GUIDANCE – Expiration Dating and Stability Testing for Human Drug Products.

- Federal Register. Current Good Manufacturing Practice Requirements for Combination Products.

- International Council for Harmonisation – Quality http://www.fda.gov/drugs/guidancecomplianceregulatoryinformation/guidances/ucm065005.htm

- Guidance for Industry ANDAs: Stability Testing of Drug Substances and Products – Questions and Answers

- Guidance for Industry and FDA Staff: Current Good Manufacturing Practice Requirements for Combination Products – Draft Guidance

- Guidance for Industry – Investigating Out-of-Specification (OOS) Test Results for Pharmaceutical Production October 2006.