One of the first things you notice about the new IVDR is that it has a series of new reports. We are now at the point in the transition where companies have started to implement the IVDR requirements, and one of the comments we often hear is that regulation is very repetitious. I must admit that at first glance I would agree, but when you take a step back and look at the flow of the documents, it makes more sense. The problem is that most manufacturers understandably are focused on remediating existing products to maintain market access; however, there is something to be learned from taking a step back and considering how these documents all fit together.

Everything starts with a good intended purpose statement. The IVDR requires a clear statement that must stipulate whether it is for screening, monitoring, diagnosis or aid to diagnosis, prognosis, prediction, or is a companion diagnostic. The intended purpose has to be included in the labeling as described in GSPR 20 (General Safety and Performance Requirements) needs to be clear and support the classification defined by the manufacturer plus all claims as described in article 7.1

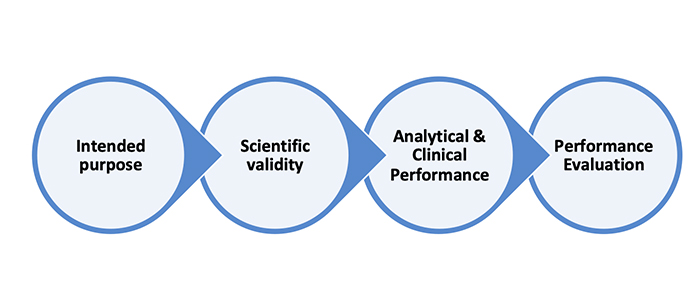

The next step when implementing the IVDR for a brand-new device would be to use the performance evaluation plan (PEP) to determine what data would be needed to support the intended purpose. Under the regulation these are described in the scientific validity, the analytical performance, and the clinical performance and performance evaluation reports. The scientific validity report documents the association of the analyte to the clinical condition or physiological state described in the intended purpose and requires a formal literature search or studies as objective evidence.

The performance evaluation plan also requires the preparation of an analytical performance report, which describes the performance necessary to meet the intended purpose and objective evidence that it has been achieved. For example, the test should have an appropriate sensitivity and specificity to meet the intended purpose, which could be different for the same analyte depending on how it is intended to be used. Finally, the clinical performance should support the populations described in the intended purpose. The data from these reports are then summarized into the performance evaluation report.

There is some cross over with the GSPR checklist, as it allows a manufacturer to identify and point to documentation that supports compliance with individual requirements but does not usually include a detailed summary of how the compliance is achieved. The analytical performance report and the clinical performance report should include a summary of the data and then a discussion and conclusion about how this meets the specific IVDR requirement and the intended use.

If we consider interfering substances as an example, this should be first identified in risk management—the PEP would then identify the necessary studies to be performed, and a report and conclusions of the study would be created. The analytical performance report then summarizes the data for all analytical studies and brings them together with a summary of the data and a conclusion about the impact of the clinical performance of the device, and the residual risk is then described in the IFU. The GSPR checklist is, as the name suggests, a list that enables a manufacturer to ensure they have addressed all the requirements, but it will lack detailed summaries and conclusions. In the past, the essential requirements checklist may have referenced many individual reports; however, it may now be more relevant to reference the APR, which in turn will reference the original reports summarized.

When compiling IVDR files based on existing devices, the APR can be used for the same function; however, in this case it is sucking in data from existing reports, summarizing the findings and making clear statements of compliance to the IVDR, which should be consistent with the intended purpose and the claims. Notified bodies are not allowed to look at your data and conclude whether it is compliant to the IVDR; they look at your discussion and conclusions, and then look at the summary data. In some cases this will require a deep dive into the full data, and then they will decide whether they agree with your conclusion.

Analytical reports created prior to the IVDR will not make clear conclusions that the requirements of the IVDR have been met. Essential requirement checklist translated into a GSPR checklist often lack IVDR conclusions and simply reference the original reports. This means there are no clear statements of compliance to the IVDR by the manufacturer. This is important, as IVDR requirements are not identical to IVDD requirements; for example the IVDR requires data from three batches of product to meet stability requirements, the ISO standard allows some flexibility, as a result a stability study compliant with the IVDD may not be compliant with the IVDR, and additional on-market data would be required. The purpose of the new IVDR reports is to summarize this data and provide clear conclusions.

When deciding how to transition IVDD files to meet the IVDR, it is important to understand the flow of documents. The PEP could be used to consider the existing data plus gaps identified in any gap analysis and help determine what additional data is required and whether this can be acquired from real-world data or whether new studies are required.

Whatever approaches are adopted for existing devices, it is important that there is an intuitive flow to enable a reviewer to find the IVDR requirement, the manufacturers conclusion of compliance to the specific requirement and locate the supporting data. Where there is repetition in a file it should be consistent, ad if the intended purpose is repeated, it should be identical. There is a fine balance between ensuring documents are stand alone and creating documents that will be difficult to keep consistent as they are updated. Where possible it is good to point back to a single point of truth; however, you still have to take readability into consideration, and it is valuable to consider future proofing when creating documents.

In summary, the IVDR is more prescriptive. There are many places it states “shall” and objective evidence has to be supplied to demonstrate compliance; however, there is still some flexibility in the way this documentation is presented. It is important to understand the IVDR document flow and consider how to implement this flow for the transition of existing devices as well as new devices. Using the quality management system described by the IVDR to drive compliance for existing as well as new devices embeds this in your corporate culture from the outset and prepares you for the future.

Resource

1. Regulation (EU) 2017|746 of the European Parliament and of the Council of 5 April 2017 on in vitro diagnostic medical devices and repealing Directive 98/79/EC and Commission Decision 2010/227/EU.