Manufacturing 101: What is Metal 3-D Printing?

The pace of technological growth and change is higher today than perhaps at any other point in human history. Blockchain, artificial intelligence, augmented/virtual reality—the list of potentially revolutionary breakthroughs now at our fingertips is long and growing. Of all the promising nascent technologies out there, however, none is closer to bringing real change to the way we live and work than additive manufacturing.

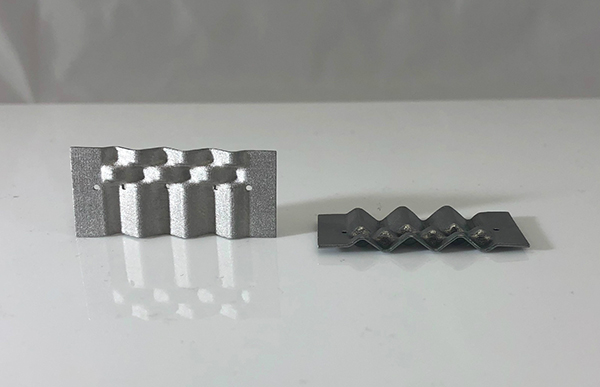

Otherwise known as metal 3D printing, this method of making things is almost literally the inverse of more traditional processes. Rather than molding an indeterminate hunk of raw materials into specific parts or components, additive manufacturing uses the specific volumes of material required to sculpt objects layer by layer.

This unique process comes with a host of advantages that expand the boundaries of feasibility in manufacturing. More practically, however, those unfamiliar with metal 3-D printing should note that its share of the total manufacturing market is growing rapidly.

Different Metal 3-D Printing Processes

Powder Bed Fusion (PBF)

PBF is one of the most popular additive manufacturing techniques and involves laser sintering and electron beams. A layer of metal powder is rolled onto a build tray, and a laser or electron beam melts the powder. Each layer is fused together to create a part. PBF offers a wide range of materials and high tolerances but is slow and difficult to repeat. Powder bed fusion is best for low-volume, high-end applications such as patient-specific prosthetics.

Binder Jetting

Binder jetting is a powder bed process that uses an inkjet to deposit a liquid binder onto a powder layer in the shape of the part. The resulting “green part” of bonded powder needs to be sintered in a furnace to achieve final density. While binder jetting is a low cost and fast process, the parts require infiltration to prevent shrinkage and post-processing to improve the surface finish. Binder jetting is best for high-volume, low-cost applications like surgical instruments.

Metal Extrusion FFF/FDM

Metal extrusion is the process of depositing a heated metal filament onto a platform to build a part in layers. The metal filament is a combination of thermoplastic and metal particles. The part is sintered in a furnace to melt the plastic away and fuse the metal together. Metal extrusion can achieve high precision with fine layers for a low-cost. However, metal extrusion has unpredictable part properties because the nozzle requires steady and constant pressure, which is hard to maintain. Metal extrusion is best for cost-effective metal prototyping.

Directed Energy Deposition (DED)

Directed energy deposition (DED) is the process of combining metal wire or powder with an energy source to deposit material onto a build tray. DED is similar to welding—a nozzle deposits metal feedstock while a laser or electron beam melts it. DED’s rapid material deposition results in rapid production time and fully dense parts, making it the fastest additive manufacturing technology to date. DED can also be used for adding metal to existing metal parts, making it great for welding and repair applications. However, DED is less accurate, resulting in a very rough surface finish that requires post-processing. DED is best for the rapid production of large parts.

Material Jetting

Material jetting, similar to binder jetting, involves jetting metal material through a nozzle and onto a build tray and sintering the resulting part in a furnace. The process produces ultra-thin layers that result in very high-resolution surface finishes. Unfortunately, material jetting is a very slow and expensive process. Material jetting is best for small parts with complex internal geometries and tight tolerances.

Metal 3-D Printing’s Rapid Growth

The range of applications and industries that are being touched by AM is virtually endless. Many of the specifics of where AM fits into a given industry are determined by the material requirements of the pieces and parts being manufactured. Are they plastic? Ceramic? Some type of metal? All of these material types and more can be 3-D printed in 2018, but it’s the market for customized metal products that is growing and developing the fastest.

The advantages that metal AM brings over conventional manufacturing techniques are specific but numerous. While it’s not a cure-all or miracles solution, there are many manufacturing applications that can be handled more efficiently with metal 3-D printing than any other technique. The detailed analysis that should accompany any decision to integrate AM into a process is mostly outside the scope of this article, but a few introductory points should help ground the discussion.

Advantages of Metal AM for the Medical Field

In general, metal AM is the right solution for production of components that are intricate, specific, or both. The three primary advantages are:

- Mass customization

- Lower cost in low volumes

- Design flexibility and freedom

The additive process allows the formation of complex internal geometries that would be nearly impossible to achieve otherwise. AM allows for custom parts to be made at high volumes, because it doesn’t require any molds. Further, it’s much easier and less expensive to produce a high-quality but unique part by importing a digital drawing than it is to tool and set up a machine shop. AM is not as efficient as other methods like injection molding at higher volumes, but for highly detailed, low-run applications, it’s a clear winner.

This brings us, of course, to medical devices. Perhaps no other industry vertical is as characterized by its dependence on custom equipment. Common medical applications of metal 3D printing include joint replacements, stents, dental inserts and prosthetics. What each of these has in common is the involvement of a part that is singular in its size and shape.

Specific Examples: Joint Replacements and Surgical Tools

Consider something like a hip replacement. A hip has a demanding list of traits that it must fulfill perfectly to perform its function. First, it has to fit the patient’s unique socket shape. Next, it has to be able to flex, turn and rotate in at least a reasonable imitation of the original. Finally, it must be safe to implant into a patient’s body.

Ten years ago, an Italian surgeon inserted the world’s first 3-D printed hip into a patient in need of a replacement. Made of a titanium alloy, there were early questions about how the joint would hold up. Today, the pilot patient is doing “extremely well,” and some experts think it may be reasonable to expect these joints to last 20 years or more. At least 100,000 3-D printed metal hip joints have now been used as replacements.

Another prominent example is surgical tools, which have only recently begun to be 3-D printed in any numbers. A very delicate open heart surgical procedure called keyhole heart surgery was an excellent candidate for innovation. Surgeons wanted a tool that they could dismantle and pass through a tiny incision in the heart. A 3-D printed tool made of stainless steel powder emerged as the solution.

In just three months, the entire suturing procedure was revolutionized. What’s more, the product development process cost less than $20,000. Examples like these are becoming increasingly commonplace across all branches of medicine. While metal 3-D printing isn’t the perfect manufacturing solution for every industry, it has already changed how we think about what’s possible in medical devices. The leaps forward promise to keep coming.