Science Fiction Meets Nano-Robots

In an innovative application in which science fiction meets reality, researchers are exploring the use of nano-robots in the bloodstream to autonomously carry out various therapeutic operations. The Max-Planck Institute (MPI) for Intelligent Systems, located in Stuttgart, Germany, has developed two different micro-swimmers for this use. Researchers anticipate that future applications of nano-robots will involve introducing therapeutic agents directly into a tumor. “Theoretically, at the size of our construction, application within the cell would be conceivable,” says Peer Fischer, head of the working group Micro-, Nano- and Molecular systems at MPI for Intelligent Systems. However, it might some years until this science fiction becomes a reality.

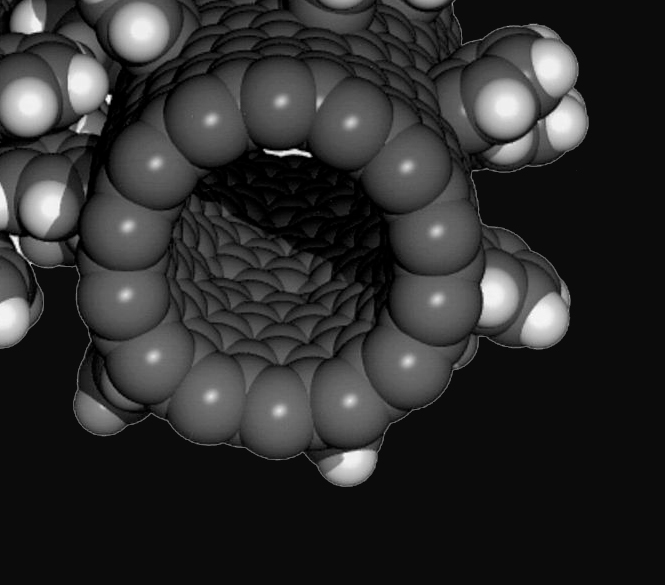

Measuring 100 nm in diameter and 400 nm in length, the micro-swimmer is a type of clam that moves forward by opening and closing A mini-screw is set into motion via a rotating magnetic field that is applied externally. The micro-swimmers are manufactured using a 3-D printing process and the materials used, including polydimethylsiloxane, are biocompatible.

Precise, Miniaturized Solutions

As the demand for smaller systems remains constant in the medical device industry, many miniaturized solutions have become a reality. In addition, the industry is also demanding micro-structures and the integration of optical and electrical functions in inexpensive components, according to Peter Kirkegaard, CEO of IMT Masken und Teilungen AG (Switzerland). IMT addresses this need by using manufacturing technologies derived from the semiconductor industry. Based upon glass, the company manufactures micro-channels, clearance holes, electrodes, optical and electrical coatings, waveguides and grating. Structures have dimensions as small as 150 nm with applications that include lab-on-a-chip systems. Micreon GmbH is among the specialists in micro-processing and uses ultrashort pulse lasers within the pico and femto range. Lasers play an increasingly important role in manufacturing medical implants, instruments and measurement devices in the device industry due to the high level of precision and quality required. In the area of ultrashort pulse laser techniques especially, there is an increasing number of application possibilities. One example is stents that are made from organic materials. Since bioresorbable polymers are very sensitive to temperature, the femtosecond laser is used for manufacturing refined and structured components, as it does not cause damage.

Smaller Designs for 3-D Images of Tissue Structures

Another current trend in miniaturization are optical techniques for improved diagnostics. In a joint effort that began in April, the Fraunhofer Institute for Electronic Nanosystems (ENAS), the EDC Electronic Design Chemnitz GmbH and Preciseley Microtechnology Corp. developed a micro-opto-electro-mechanical system (MOEMS) for optical coherence tomography (OCT). The solution is expected to generate high-resolution in-vivo OCT diagnostics. When miniaturizing the design, increasing the precision of OCT can be achieved using integrated piezoelectric sensors and an application-specific integrated regulation circuit. This approach integrates high-precision coherence tomographic images into an endoscope and enables non-invasive 3-D imaging of tissues structures. OCT is used in a variety of medical fields, such as ophthalmology for the non-invasive detection of retinal diseases. Using OCT it is possible to obtain 3-D images of the composition of tissue structures. Compared to other techniques, the technique involves a high level of penetration depth into the tissue with a high level of resolution. In contrast to sonography, OCT is not based on an acoustical method, but rather on optical interferometry (distance measurement).

These technologies will be discussed at the upcoming COMPAMED 2015 tradeshow. Products range from tiny sensors all the way to packaging machines that fill entire rooms, from innovative materials to refined microsystems, from mobile diagnostic devices all the way to electronic manufacturing services (EMS). In the future, 3-D printing will become a focus at the event, as 31% of the companies at the show rely on the manufacturing method and 35% plan to use it in the foreseeable future.